|

Rolling Thin Film Oven

Model CS 325B

AASHTO Designation

T240

ASTM Designation

D2872

For more information or pricing on any of these

products, please contact us.

| The rolling thin film

oven test is used to measure the effect of heat

and air on a moving film of semi-solid asphaltic

materials. The results of this treatment are

determined from measurements of the asphalt

properties before and after the test. |

|

General Description

The CS325-B precision oven is

designed for the specific requirements in the State of

California method 346, AASHTO T240 and ASTM

D2872.

Repeatability of the test is

directly related to the accuracy with the oven temperature

can be maintained to the specific standard temperature of

163°C, and the reproducibility of the thermal rise time of

the system. The CS325-B has been designed to perform or

exceed the specification requirements as detailed by

AASHTO and ASTM.

The oven temperature is sampled

by a precision RTD sensor exposed to the supervised

environment. The thermal mass of the sensor is extremely

low having a thermal/electrical time constant measurable

in seconds. The controller accepts the signal from the RTD

sensor and precisely displays the process temperature

while providing an accurate output control signal to

maintain the process at the required control point. The

controller operates in the PID mode. It has a programmable

auto tune feature which automatically establishes the

tuning constants. The PID constants may be fine-tuned by

the operator at any time, if desired, and secured from

further modification by unauthorized personnel. The

controller employs a unique suppression feature which

allows for the quickest response time without excessive

overshoot. Dual 4 digit displays allows viewing of the

process temperature and set point simultaneously.

The CS325-B oven is double walled and designed

to conform exactly to the AASHTO and ASTM

specifications for interior dimensions and location of

critical components. |

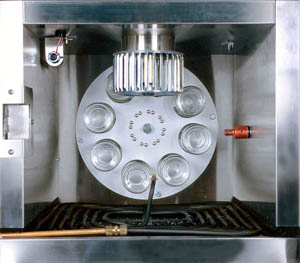

INTERIOR VIEW

Net Weight

Shipping Weight

Overall Dimensions

Shipping Dimensions |

254 lbs.

380 lbs.

40"W 36"H

26"D

48"W 46"H

35"D |

|

|

SPECIFICATIONS

|

Construction |

16 gauge welded

steel exterior.

18 gauge corrosion resistant stainless steel interior. |

| Insulation |

3-1/2 inches of

high density fiberglass insulation |

| Controller |

Programmable micro

processor UL listed |

|

Display |

Temperature - 4

digit red LED's

Set point - 4 digit green LED's |

|

Thermal Protection |

Prevents oven from

overheating in the event of control failure |

| Temperature Range |

Ambient to 200°C |

|

Vents |

Double exhaust

vents for dissipation of expended volatile from

specimen |

| Flow Meter |

Range 200 - 14000

ML/MIN |

| Air Pressure Gauge |

Range 0 - 100 P.S.I. |

| Air Flow Adjustment |

Needle valve (long

taper) |

| Heat Exchanger |

5/16" dia. copper

tube |

|

Blower Motor |

Model - Grainger

6K092 Thermal protection (manual reset) |

|

Rack Motor and Gear Reducer |

Model - NSY-12RG

Bodine Protection (fuses) |

|

Voltage |

240v AC 50/60 Hz,

single phase, 9.3 amps, 2240 watts |

PARTS

LIST

CS325B RTF OVEN PARTS

LIST

|

Item # Description

325:01B...Bodine Rack Motor

60cycle

325:01A...Dayton Rack Motor 50cycle

325:02......Heating Coil

325:03......Power Switch

325:04......Sample Rack Switch

325:06......Blower Switch

325:07......Sample Rack Assembly

325:08......Sample Rack Spindle Bushing-(1 set)

325:09B...Blower Motor 60cycle

325:09A...Blower Motor 50cycle

325:10......Blower Motor Flexible Coupling

325:11......Blower Spindle Housing

325:12......Blower Shaft-3/8 Diameter

325:13......Blower Bushings

325:14......Squirrel Cage

325:15......Top Motor Mount

325:16......Air Heating Coil

325:17......Flow Meter Adjustment Valve

325:20......Moisture Indicator

325:21......Air Regulator

325:26......Sample Bottles-Clear

325:27......Sample Bottles-Frosted

325:28......Air Nozzle

325:29......Rack Shaft

325:30......Rack Fingers-(set of 8)

|

Item # Description

325:31...Transformer

325:32...Rack Spindle Housing

325:33...Silicon Gasket for Door (per inch)

325:33B.Silicon Gasket for Door Glass (per inch)

325:35....Plastic Handle for Door

325:36....Handle Assembly (include #35)

325:37....Silica Gel-1LB can

325:38....Pyrex Plate

325:39....Thermometer

325:40....Chain

325:41....Transite Plate

325:42....Latch-Set (inside)

325:44....DC Motor Control

325:51A.RTD Sensor

325:51B.RTD Sensor

325:53....Controller-Series B

325:54....lst Micro Switch Cvr

325:55....Jar Tongs

325:56....Drive Gear 25B15(small 60Hz)

325:57....Drive Gear 25B25(medium 50Hz)

325:58....Drive Gear 25B30 (large 60Hz)

325:60....Bearing Housing

325:61....Manual

325:62....Dry Air System

325:63....Precision Thermostat Switch |

For more information or pricing on any of these

products, please contact us.

|